The proper upkeep of kitchen tools forms a fundamental step for restaurant kitchens to operate efficiently. Every bit of kitchen equipment actively participates in both food preparation and delivery duties in restaurant kitchens. An unexpected breakage of any device leads to major service interruptions along with extended wait times. Routine maintenance procedures protect kitchens from operational problems which allow all processes to operate without interruption. Equipment longevity increases as a result of proper care because it decreases repair expenses and enhances kitchen operational efficiency.

Routine Checks and Proactive Repairs

The practice of maintaining kitchen equipment requires inspecting at scheduled intervals along with fixing issues before they become serious. Checking refrigerators and freezer temperatures on a regular basis helps maintain their operational efficiency, preventing any food spoiling. Staticamine routinely examining stovetops alongside ovens and fryers helps spot accumulations and damages that prevent fire risks while preserving normal temperatures. Preventive maintenance involving basic tasks like cleaning filter elements alongside checking gaskets and replacing undermined components stops more serious expensive system breakdowns from occurring. Small yet fundamental tasks form the basis of avoiding unexpected restaurant downtimes that would harm your establishment’s ability to serve customers.

Establishing a Maintenance Schedule and Assigning Responsibilities

A clear equipment inventory and systematic planning are needed for carrying out regular maintenance operations. Staff members need to undergo training on suitable maintenance techniques for each appliance to help workers understand what actions they should perform. The kitchen staff performs tasks such as grease trap cleaning and oven temperature checks but professionals handle dishwasher servicing and refrigerator calibration tasks which management oversees. The process will maintain equipment quality while decreasing operational halts and sustaining smooth kitchen operations.

Timely Repairs to Prevent Further Damage

Repair operations must be performed promptly to achieve the same preventive maintenance benefits. An equipment failure or indicator of wear calls for immediate action to stop both the equipment’s deterioration and further operational breakdowns.

Postponing fixed issues so they develop into major problems leads to extended operational interruptions. A technician should handle all equipment inspection and repair work when a malfunction is detected. Using experienced technicians along with qualified vendors enhances equipment repairs because they can complete work effectively while minimizing future breakdowns.

Maintaining Your Kitchen Display System

To preserve kitchen operational efficiency a kitchen display system (KDS) must function continuously. A KDS system transports digital orders to kitchen staff members which both standardizes processes and diminishes possible human errors. The KDS remains an equipment that requires constant maintenance practices to avoid operational disruptions. A periodic inspection of both hardware functioning and software updates is required for the KDS device. Maintaining a schedule for inspecting your KDS includes examining cable connections and monitoring display screens thereby helping you prevent unexpected system malfunctions in busy service times.

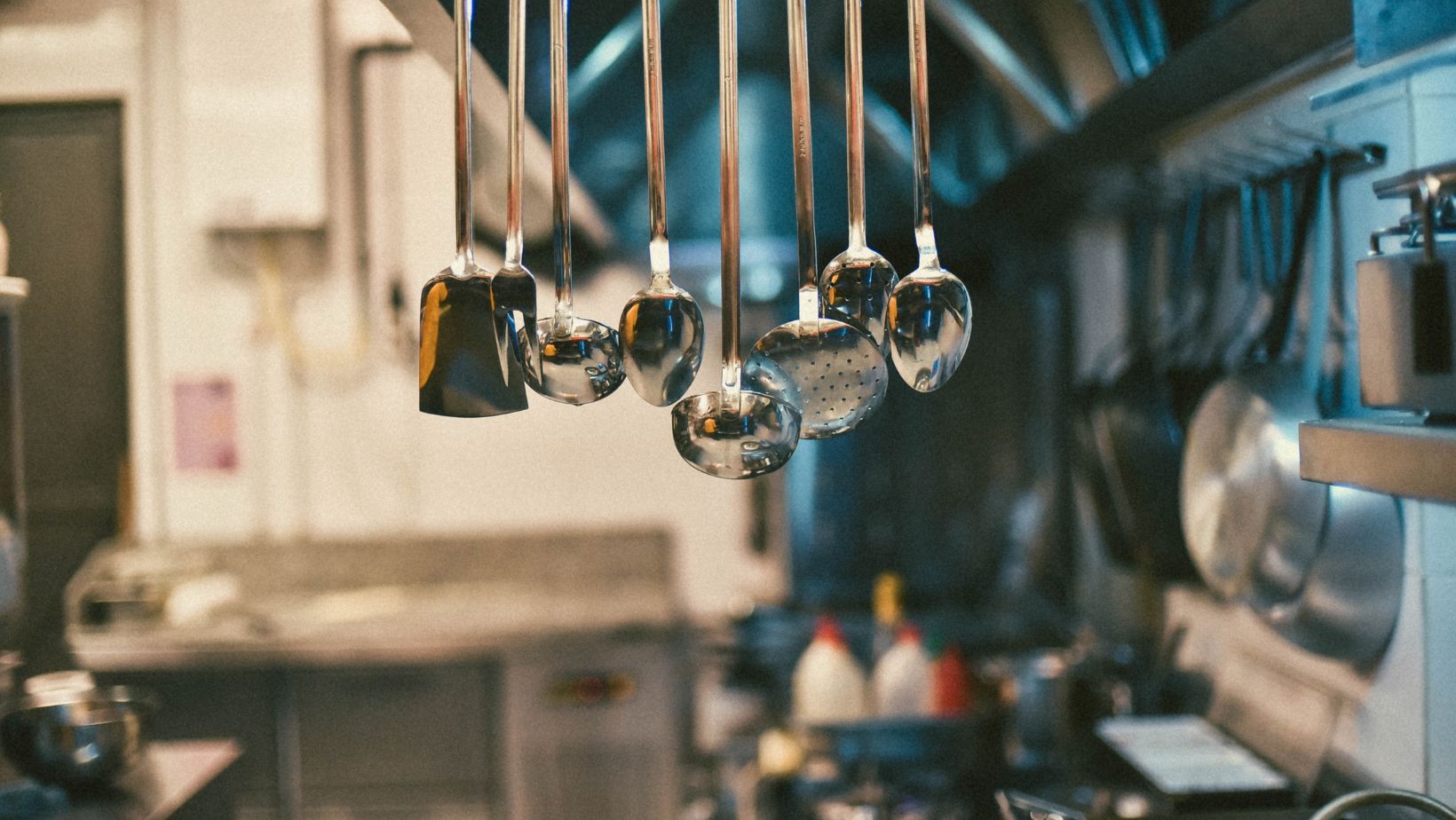

Maintaining Smaller Tools and Appliances

Proper device maintenance practices must not disregard smaller operating tools and appliances which normally receive minimal attention. The daily kitchen operations rely heavily on kitchen tools including knives and mixers and blenders. By following regular knife sharpening routines as well as mixer cleaning protocols both tools will remain effective when required. Improper care of smaller tools within the kitchen results in operation inefficiency which inevitably delays food production. The upkeep of fundamental kitchen tools enables staff to perform their work better so the kitchen facility operates efficiently throughout peak service periods.

The Importance of Record-Keeping for Equipment Maintenance

Kitchen equipment maintenance depends heavily on proper recordkeeping operations. The kitchen team can predict when future maintenance will be required through maintaining a record that documents all maintenance activities and parts replacements and equipment repairs. The collected data helps staff recognize recurring equipment breakdowns for better decisions about equipment succession. A kitchen can expect and respond to upcoming hurdles through updated maintenance logs which prevent unexpected incidents.

Proper care of kitchen equipment needs continuous dedication together with active monitoring to ensure success. A well-established equipment upkeep system combined with proper staff training about maintenance practices and prompt repair management protects your kitchen from breakdowns to ensure continuous operation. The reliability of your equipment determines the success of your kitchen whether you operate at a big restaurant or smaller facility. By committing to regular equipment maintenance and quick service repairs you will prevent business disruptions that disrupt staff operations and daily customer needs.