Imagine navigating a vast ocean without a compass—it’s nearly impossible to find your way. In the oil and gas industry, software solutions act as that essential compass, guiding you through the complexities of exploration, drilling, and production. These tools can transform raw data into actionable insights, optimizing every phase from asset management to compliance tracking. But how exactly do these systems integrate to enhance operational efficiency and safety? Let’s explore how you can leverage these technologies for maximum productivity and streamlined processes in your operations.

Exploration and Drilling Software

Exploration and drilling software streamlines the complex processes of identifying potential hydrocarbon reserves and planning efficient extraction strategies. You’ll find that seismic analysis is at the core of this software, allowing geophysicists to interpret subsurface geology with precision. By using sophisticated algorithms, the software processes seismic data to create detailed three-dimensional subsurface models. This helps you pinpoint the most promising locations for drilling, reducing both time and financial risk.

Next, drilling simulation tools come into play. They let you model different drilling scenarios before actual field operations begin. These simulations consider variables like rock hardness, pore pressure, and potential hazards. By running these simulations, you can optimize drilling parameters and anticipate challenges, ensuring a smoother operation. Additionally, the software can integrate real-time data from sensors, enabling you to make data-driven decisions on the fly.

Incorporating seismic analysis and drilling simulation into your workflow enhances efficiency and minimizes environmental impact by reducing unnecessary drilling. Advanced visualization tools make it easier for multidisciplinary teams to collaborate, ensuring everyone is on the same page. Ultimately, leveraging these technologies empowers you to make informed decisions, maximizing resource extraction while mitigating risks.

Production Optimization Tools

Production optimization tools enhance your ability to maximize output and efficiency by fine-tuning the various stages of hydrocarbon extraction and processing. Leveraging advanced reservoir simulation models, you can predict fluid behavior and reservoir performance under various scenarios, enabling you to make data-driven decisions. These simulations utilize complex algorithms to forecast production rates, optimize well placement, and manage reservoir pressure.

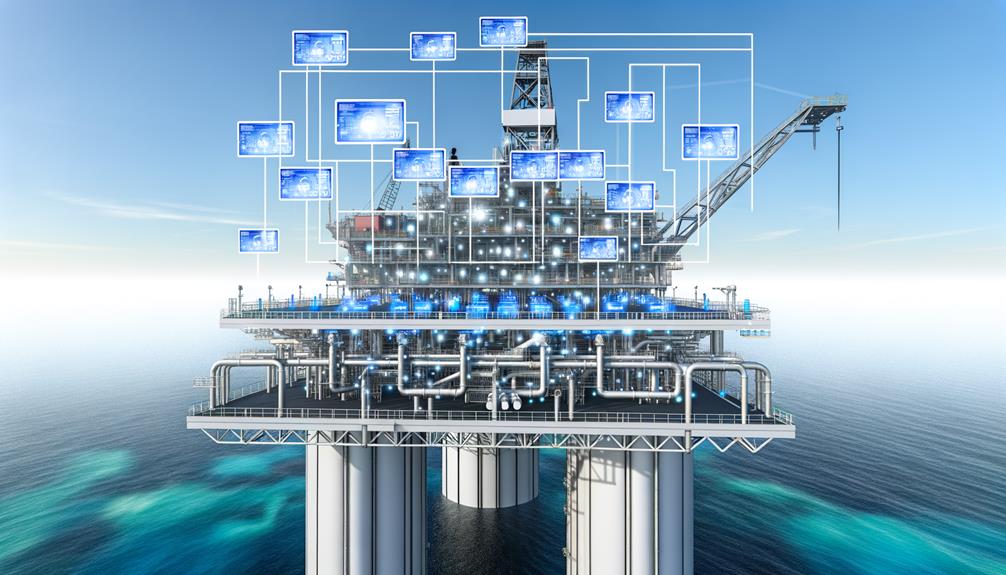

Remote monitoring is another critical component of production optimization. By integrating IoT sensors and automated data collection systems, you can continuously track key performance indicators such as flow rates, pressure, and temperature in real time. This real-time data allows for proactive adjustments and immediate responses to operational anomalies, minimizing downtime and enhancing productivity.

Additionally, production optimization tools incorporate sophisticated analytics to interpret historical data, identify trends, and predict future performance. This helps you not only to troubleshoot existing issues but also to anticipate and mitigate potential problems. Advanced machine learning algorithms can identify patterns that traditional methods might overlook, offering you deeper insights into your operations.

Asset Management Systems

Having optimized production processes, the next focus is on asset management systems that ensure the longevity and efficiency of your operational infrastructure. Effective asset management is critical in the oil and gas industry, where the asset lifecycle can span decades and involve significant capital investment. By implementing advanced asset lifecycle management software, you can monitor and maintain your equipment more efficiently.

Asset management systems provide comprehensive equipment tracking, which allows you to keep a detailed record of each asset’s performance, maintenance history, and current condition. This real-time data enables predictive maintenance, reducing downtime and extending the life of expensive machinery. You’ll also gain insights into asset utilization, ensuring that every piece of equipment is operating at optimal levels.

Integrating these systems with your existing operations can streamline workflows and improve decision-making. For instance, automated alerts for scheduled maintenance or potential issues can help you address problems before they escalate, thereby minimizing operational disruptions. Moreover, the analytical tools embedded in these systems allow you to forecast future asset needs and budget accordingly.

Incorporating asset management systems into your operations not only safeguards your investments but also enhances overall efficiency, ensuring that your infrastructure remains robust and reliable for years to come.

Health, Safety, and Environment Solutions

Ensuring robust health, safety, and environment (HSE) solutions is paramount in the oil and gas industry, as it not only protects your workforce but also minimizes environmental impact and regulatory risks.

Effective HSE software solutions enable you to streamline incident reporting, ensuring that every event, no matter how minor, is documented promptly and accurately. This meticulous documentation is crucial for analyzing patterns and preventing future incidents.

Compliance tracking is another critical component of HSE solutions. Given the stringent regulations governing the oil and gas industry, your operations must adhere to local, national, and international standards. Advanced HSE software facilitates real-time compliance tracking, allowing you to monitor regulatory requirements and implement necessary changes proactively. This ensures that your company remains compliant, avoiding costly fines and legal repercussions.

Moreover, integrating HSE solutions into your operations enhances your ability to conduct comprehensive risk assessments. By leveraging these tools, you can identify potential hazards, evaluate their impact, and devise effective mitigation strategies. This proactive approach to risk management not only safeguards your personnel but also optimizes operational efficiency, ensuring that safety and productivity go hand in hand.

Data Analytics and Predictive Modeling

Leveraging data analytics and predictive modeling in the oil and gas industry empowers you to make informed decisions by transforming raw data into actionable insights. By utilizing real-time monitoring systems, you can continuously track operational parameters, detecting anomalies and predicting equipment failures before they occur. This proactive approach not only minimizes downtime but also enhances operational efficiency.

Advanced simulations play a crucial role in predictive modeling, allowing you to create detailed digital twins of your assets. These simulations enable you to test various scenarios and optimize processes without risking actual resources. By integrating historical data with current operational metrics, predictive models can forecast production trends, helping you plan maintenance schedules and allocate resources more effectively.

Incorporating machine learning algorithms into your data analytics framework further refines these predictive capabilities. These algorithms can identify patterns and correlations within vast datasets that might be missed by traditional analysis methods. This leads to more accurate predictions and better decision-making.

Conclusion

By leveraging oil and gas software solutions, you’re not just optimizing operations; you’re revolutionizing the way you tackle industry challenges. From exploration to production, asset management to safety, and data analytics to predictive modeling, you gain unparalleled efficiency and insights.

Imagine transforming your decision-making processes with cutting-edge technology—how much further could you push your operational limits? Embrace these tools and stay ahead in the ever-evolving oil and gas landscape.