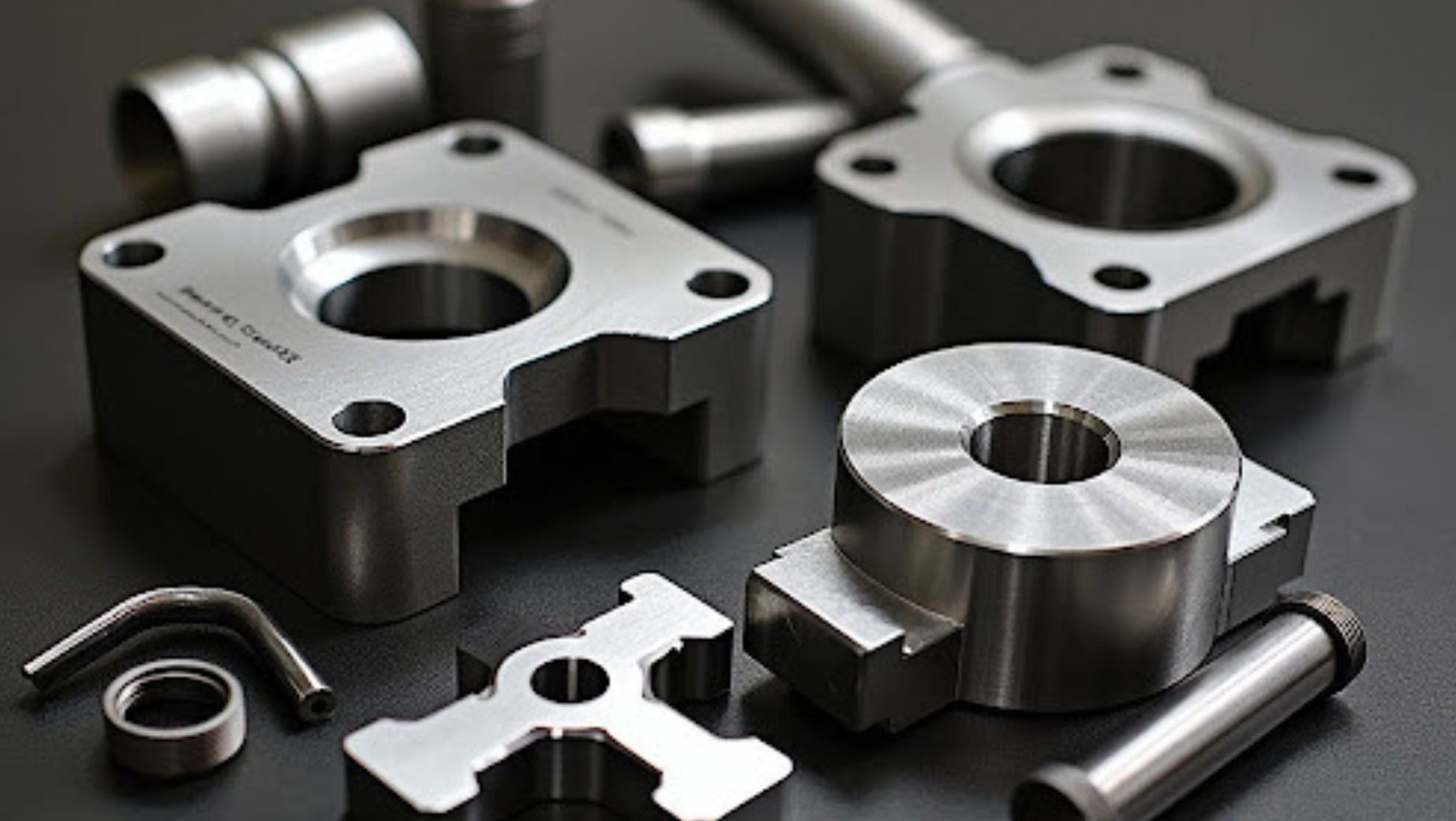

For businesses in manufacturing, CNC (Computer Numerical Control) machined steel parts offer several competitive advantages that go beyond basic material properties. Steel, particularly stainless steel, plays a crucial role in modern industries where precision, durability, and efficiency are key factors. Here’s how using CNC-machined steel parts can benefit your business.

Increased Operational Efficiency

One of the most significant advantages CNC machined steel parts provide for businesses is enhanced operational efficiency. CNC machines are programmed to perform precise cuts, drilling, and shaping, which minimizes human error and reduces downtime. This level of automation allows businesses to meet deadlines faster while maintaining high-quality standards.

The use of steel parts, particularly those made of stainless steel, further enhances efficiency due to their strength and longevity. CNC machining produces components that are durable enough to handle heavy usage without the need for frequent replacement. This minimizes the need for constant part reordering, cutting down on operational bottlenecks.

Cost Reduction and Long-Term Savings

For any business, controlling costs is essential for profitability. While steel, especially stainless steel, may initially seem more expensive compared to other materials like aluminum, the long-term benefits justify the investment. The durability of CNC machined steel parts translates to fewer replacements and repairs over time, leading to cost savings on maintenance.

In addition, CNC machining ensures minimal material waste during production, thanks to its precise cutting and shaping abilities. For businesses focusing on lean manufacturing principles, this can significantly reduce material costs and help with sustainability initiatives. Yijin Hardware CNC steel parts offer custom machining solutions that optimize production efficiency while reducing overhead costs.

Scalability and Flexibility

CNC machining offers businesses flexibility in production, allowing for easy scalability. Whether you’re producing large quantities of steel components or need custom one-off parts, CNC technology accommodates both high-volume and small-batch orders without compromising on quality. This flexibility is crucial for businesses that need to adapt quickly to changing market demands or customer requirements.

Steel’s versatility in CNC machining also allows businesses to serve a wide range of industries, from automotive and aerospace to healthcare and consumer electronics. This broad application base opens new market opportunities and can drive revenue growth.

Improved Product Quality and Precision

Product quality is the cornerstone of any business’s reputation, especially in industries where precision is non-negotiable, such as aerospace, medical devices, or electronics. CNC-machined steel parts offer superior accuracy, ensuring that every component produced meets exact specifications. This level of precision reduces the likelihood of part failure, enhancing the reliability of the final product.

For businesses, this translates to fewer defective products, reducing the costs associated with recalls, returns, or warranty claims. Moreover, high-quality components lead to satisfied customers, improving client retention and fostering positive reviews that drive new business.

Streamlined Production Process

Using CNC-machined steel parts simplifies and streamlines the production process. Since CNC machines can execute multiple complex operations—such as milling, turning, and drilling—in one setup, businesses can reduce production time and labor costs. This automation allows manufacturers to produce steel components faster, helping to meet tight project timelines.

Additionally, CNC machining is ideal for businesses that require frequent product iterations or design changes. Instead of retooling for each adjustment, modifications can be quickly implemented through programming changes, ensuring continuous production without the need for expensive downtime.

Long-Term Durability

In industries where reliability is paramount, such as construction or heavy machinery, CNC-machined steel parts offer superior durability. Components made from stainless steel, for instance, resist corrosion, wear, and extreme temperatures, ensuring long-term performance. This robustness reduces the risk of part failure, lowering repair costs and ensuring consistent production output.

Businesses that rely on machinery and equipment for their daily operations benefit from steel’s long-term durability, as it reduces downtime associated with part failures or maintenance.

Enhanced Brand Reputation

Producing high-quality, reliable products can significantly enhance a business’s reputation in the marketplace. CNC-machined steel parts enable companies to offer their customers durable and precision-engineered components, setting them apart from competitors who may use less reliable materials or methods. In sectors where quality is a deciding factor, such as automotive or aerospace, this reputation can be a key differentiator.

A well-regarded brand can command premium prices and attract loyal customers, ultimately boosting profitability. Businesses that invest in CNC-machined steel parts as part of their manufacturing process can build trust with clients and establish themselves as leaders in their industry.

Conclusion

CNC machined steel parts provide businesses with a myriad of benefits, from cost savings and improved efficiency to high-quality outputs and brand enhancement. For companies looking to stay competitive, embracing CNC machining technology for steel components is not just an option—it’s a strategic imperative. Whether you are scaling production or focusing on custom manufacturing, CNC-machined steel parts will drive operational success and foster long-term business growth.