When you consider the backbone of utility infrastructure, wire products might not be the first thing that comes to mind, yet they’re indispensable. From power transmission wires that keep the lights on to telecommunications cables that ensure your internet connection, these products are engineered for reliability and efficiency. They’re built to endure harsh environments and maintain performance standards. But what makes these wires so crucial, and how do they adapt to evolving utility demands? There’s more to uncover about the innovations and technologies behind these essential components.

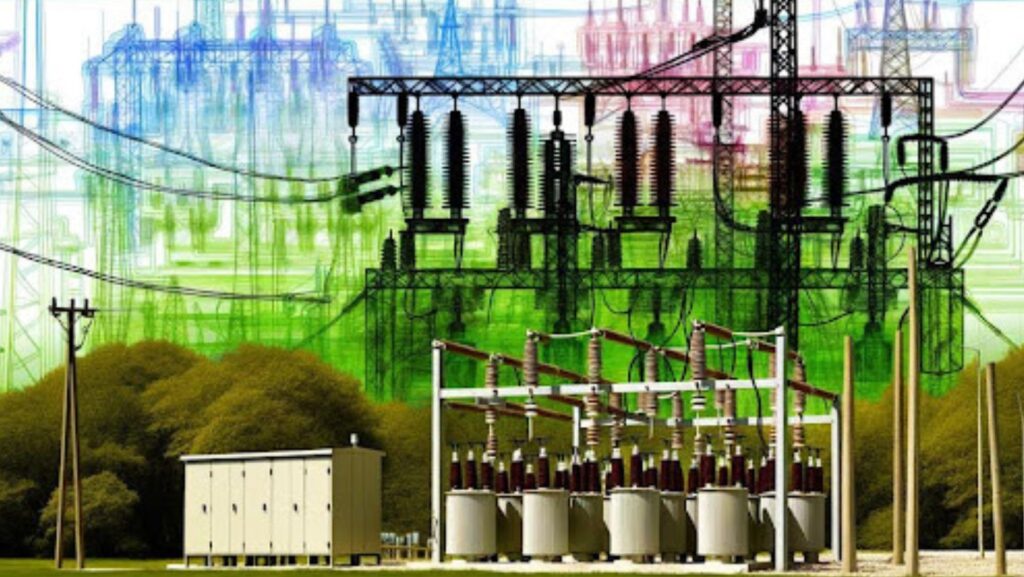

Power Transmission Wires

Power transmission wires, the backbone of any utility’s infrastructure, are engineered to efficiently transport electrical energy over long distances with minimal loss. When selecting these wires, you must consider the conductor materials used. Copper and aluminum are the predominant choices due to their excellent electrical conductivity. Copper, despite being more expensive, offers superior conductivity and tensile strength, making it ideal for high-demand applications. Aluminum, on the other hand, is lighter and more cost-effective, suitable for less demanding applications.

Insulation types are equally critical for ensuring the reliability and safety of power transmission wires. Polyethylene (PE) and Cross-Linked Polyethylene (XLPE) are commonly used due to their exceptional dielectric properties. PE is favored for its moisture resistance and low dielectric constant, making it ideal for underground and underwater installations. XLPE, with its higher thermal resistance and mechanical strength, is preferred for overhead lines and locations where high temperatures are a concern.

Choosing the right combination of conductor materials and insulation types is essential for maximizing efficiency and longevity in your power transmission infrastructure. By understanding these components, you can ensure your utility’s network remains robust and reliable.

Telecommunications Cables

In the realm of modern utilities, telecommunications cables play a pivotal role in ensuring seamless data transmission and connectivity. As an expert in the field, you understand that the backbone of today’s communication infrastructure relies heavily on fiber optics and coaxial cables.

Fiber optics, with their superior bandwidth and minimal signal loss, are indispensable for high-speed internet, long-distance data transmission, and extensive network backbones. These cables use light to transmit data, allowing for rapid and reliable communication over vast distances, which is critical for both urban and rural deployments.

Coaxial cables, while older than fiber optics, remain crucial for specific applications. You’ll find them particularly useful in delivering cable television and broadband internet services where medium-range data transmission suffices. Their design, which includes a central conductor, insulating layer, metallic shield, and outer cover, provides robust protection against electromagnetic interference, ensuring consistent signal quality.

When selecting telecommunications cables, consider the specific requirements of the application, whether it’s the unmatched speed and capacity of fiber optics or the tried-and-true reliability of coaxial cables. By understanding these nuances, you can make informed decisions that optimize the efficiency and durability of your utility infrastructure.

Water Distribution Wiring

When planning water distribution systems, incorporating robust wiring solutions is essential to ensure reliable monitoring and control of water flow and pressure. High-quality wiring enables precise data transmission from sensors and meters, critical for maintaining optimal system performance.

Start by selecting wires with insulation materials suited for the harsh conditions of water distribution environments. Pipe insulation, often used to prevent heat loss and condensation, also protects wiring from moisture and temperature fluctuations. This dual-purpose insulation enhances the longevity and reliability of your wiring infrastructure.

During meter installation, use durable, water-resistant cables to connect meters to your control systems. These connections are vital for accurate data collection and efficient system management. Ensure that the wiring layout minimizes exposure to potential damage and follows industry standards for safety and performance.

Additionally, consider incorporating redundant wiring paths to maintain system functionality in the event of a wire failure. This redundancy is particularly important in large-scale water distribution networks where uninterrupted service is crucial.

Railway System Wires

Railway system wires, essential for ensuring seamless communication and control across tracks, must be selected for their durability and ability to withstand extreme operational conditions. You need wires that can handle high mechanical stress, temperature variations, and potential interference. For railway signaling, robust wiring is crucial to maintain the integrity of signal transmission, preventing any delays or errors in communication that could compromise safety.

Track electrification demands wires with excellent conductivity and insulation. These wires must efficiently transmit electrical power to trains while minimizing energy loss. Copper and aluminum are often used due to their superior conductive properties. Additionally, the wires should be resistant to corrosion, given their exposure to outdoor elements.

In this context, selecting the right gauge and insulation material is critical. Thicker gauges might be necessary for high-current applications, while advanced insulating materials can protect against short circuits and environmental damage.

Moreover, compliance with industry standards like EN 50155 for railway applications ensures the wires meet safety and performance requirements. By carefully choosing railway system wires, you’re enhancing both the reliability and safety of your railway infrastructure.

Innovations in Wire Technology

Thanks to advancements in material science and engineering, wire technology has seen significant innovations that enhance performance and durability for utility applications. One of the most groundbreaking developments is the integration of superconducting materials. These materials exhibit zero electrical resistance at very low temperatures, enabling efficient power transmission over long distances with minimal energy loss. By incorporating superconducting wires into your utility infrastructure, you can significantly reduce operational costs and increase the grid’s overall efficiency.

Another key innovation is the development of smart grids, which rely on advanced wire technology to enable real-time monitoring and two-way communication between utilities and consumers. Smart grid systems use sensors and advanced conductors to gather and transmit data, optimizing energy distribution and improving the reliability of the power supply. By implementing smart grids, you can enhance fault detection, reduce outage durations, and better manage demand fluctuations.

Additionally, high-temperature superconductors (HTS) are gaining traction. Unlike traditional superconductors, HTS can operate at relatively higher temperatures, making them more practical for everyday utility applications. Utilizing HTS can further enhance the efficiency and resilience of your utility infrastructure, providing a robust solution for modern energy demands.

Safety in Utility Wiring

Ensuring the safety of utility wiring is paramount to preventing electrical hazards and maintaining reliable power distribution. To achieve this, you must prioritize the selection of high-quality insulation materials. These materials serve as the first line of defense against electrical faults, minimizing the risk of short circuits and electrical fires. When choosing insulation, consider properties like thermal resistance, dielectric strength, and durability under various environmental conditions.

Equally critical are grounding techniques. Proper grounding ensures that any stray electrical currents are safely diverted into the earth, preventing potential harm to both personnel and equipment. Effective grounding involves using conductive materials with low resistance to facilitate the safe dissipation of electrical energy. You should also ensure that grounding connections are robust and corrosion-resistant to maintain long-term reliability.

Regular inspections and maintenance are essential to uphold safety standards. Look for signs of wear or damage in insulation materials and verify that grounding systems are intact. Implementing these practices will significantly reduce the likelihood of electrical failures and enhance the overall safety of your utility infrastructure.

Conclusion

By understanding wire products for utilities, you’ve seen how these essential components are like the backbone of a resilient infrastructure. They ensure electricity, data, and signals flow seamlessly, even in harsh conditions.

With innovations driving efficiency and safety, and specialized products for power transmission, telecommunications, water distribution, and railways, you’re equipped to enhance utility networks.

Let’s continue to strengthen this backbone, ensuring reliable and robust utility services for the future.