Buying machine parts takes a lot of know-how. You need to understand exactly what you need to reduce costly downtime. Plus, you must maintain the parts once you have them. You can keep your machines in good shape by caring for their parts.

We put together these essential tips for buying and maintaining machine parts for you. When you’re ready to learn more, keep reading.

Tips for Purchasing Machine Parts

First, you have to buy the machine parts. There are a few tips you should know before you start the process.

Know What You Need

You must identify what parts you need before you buy them. It’s important to double-check that you’re ordering the right part. Otherwise, you’d spend more time waiting due to the returns process. In the meantime, your machines could be down.

Getting the correct parts also prolongs the life of your equipment. So, start by checking the model or serial number on the machine. This number helps you identify the machine and what parts go in it. You can also check the user manual that came with the machine for this number and other details.

Check Your Preventive Maintenance Schedule

Most machines come with a preventative maintenance schedule. Following it will help you know when to buy and replace specific parts. You can stay one step ahead, so you don’t have to worry about downtime.

Contact the machine’s manufacturers if you don’t have a schedule. They should send one to you. It’ll list the parts you should inspect and when to replace them. It’s a handy tool to have, no matter what machines your company uses.

Stock Wearable/Replaceable Parts

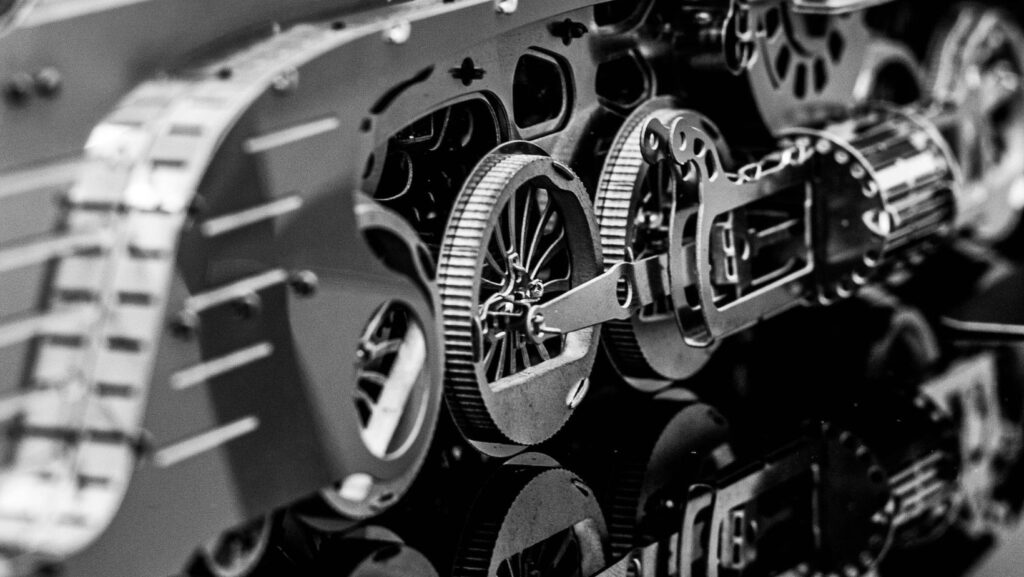

Next, it’s good to keep backups of replaceable parts that are meant to wear down over time. For example, bearings are wearable parts. They help other parts in the machine rotate, but slowly wear out.

Keeping additional bearings on hand would allow you to replace them without waiting for them to ship. They can wear out quickly, depending on the machine, so it’s best to always have some extra ones around.

Other common wearable parts include brushes, belts, switches, and filters. These components need to be replaced frequently.

Choose Quality Parts

It’s also essential that you buy high-quality parts over cheap ones. While you’d save money upfront, the cost-efficient part won’t last you as long. There’s always the chance that it’s a fake as well. It may not fit in the machine in that case.

High-quality parts last longer and perform better. So, you won’t have to replace them as frequently and can save money over time. Plus, they’ll help the machine run at its best potential.

Be Picky With Who You Purchase From

Next, you should be very careful with who you buy parts from. You only want to buy from reputable suppliers. Always conduct research into the brand and the parts before you buy. You don’t want any surprises.

You must ask to see pictures of the part if they don’t have any posted. You can check that the part is legitimate and that it’s exactly what you need.

We can help you find any Schneider Electric high-quality parts you need for your machines. So, make sure to reach out if you have questions.

Rating the Warranty

It’s also critical you look over the warranty you receive for the parts. You want protection from defects and issues caused during shipping. The warranty should protect you, so you can easily get a replacement part if something were to go wrong.

You also should familiarize yourself with the manufacturer’s return policy. That way, you’re certain you can still send the part back if it doesn’t fit your machine. It should also protect you if there’s something wrong with the part.

While you’re reviewing the warranty, it’s also good to check the customer service reviews. Other customers can let you know how easy or challenging it is to get a return completed. You may want to shop with another reliable seller if you see many negative reviews. You can usually expect to receive the same level of customer service.

Tips for Maintaining Machine Parts

Now that you have your machine parts, you must take care of them. Here’s what you can do.

Inspect Machines

You’ll need to have experts inspect the equipment often. Don’t ignore strange sounds or smells coming from the machine because they can be a sign that something’s wrong. The machine could wear itself out if left to keep malfunctioning like that.

Always take the time to inspect your equipment carefully. You can make the parts you just bought last a lot longer that way.

The sooner you address the problem, the less damage the machine takes. So, you can save money by being more proactive with your equipment. You may also discover a part that you need to replace quickly.

Verify Part Installation

You should always check on the equipment after having a new part installed. It can cause a lot of damage to the machine quickly if it’s not installed correctly. You can always have another professional verify the installation if you’re unsure.

It’s always better to double-check than to let the machine run with a part inserted incorrectly.

Keep the Machine Clean and Lubricated

Keeping the machine as clean as possible is another way to maintain the parts you order. Debris can get in between the parts and cause a lot of damage. Cleaning it frequently can prevent premature wear and tear.

Additionally, lubricating the machine when required will help prevent the parts from wearing out due to excessive friction. Always use the lubricating products the machine’s manufacturers recommend to keep it in good condition.

Taking a few preventive steps now will help keep your machine parts in outstanding condition for as long as possible.

Maintain Your Machines

To summarize, there are several ways that you can maintain your machine and the parts inside of it. You’ll want to perform regular inspections and always check that you’ve used the right parts. From there, it doesn’t hurt to double-check the installation.

When purchasing and maintaining machine parts, managing your storage space effectively is crucial for organization and efficiency. Consider using self storage units Folsom to securely store spare parts, maintenance tools, and important documents related to your machinery. These storage units provide a safe and convenient solution for keeping your items organized and protected, ensuring that everything is easily accessible when needed. By utilizing self storage, you can maintain a clutter-free workspace and have peace of mind knowing that your essential parts and tools are securely stored and ready for use.